|

|

|||||||

| The Newbies Arena Are you new to knife making? Here is all the help you will need. |

|

|

|

Thread Tools | Display Modes |

|

#1

|

|||

|

|||

|

300/400 series stainless

I'm making my first guard ever from 416 SS for a mortised tang hunting knife. I know 416 can be heat treated for some extra hardness and some more corrosion resistance but I was wondering if for this application do you fellows usually heat treat it or not?

Also, which steel do prefer for liners on a slip joint? I've seen 303,304,416,410 used. 416 I understand machines quite well but they all probably grind about the same. I'm trying to narrow down my choices for these steels and settle on something I can live with for most of my guards, bolsters, liners and pins and to make my inventory much simpler. Thanks for your help. Pat |

|

#2

|

||||

|

||||

|

303 is the free machining grade of 304 and 416 is the free machining grade of 410. Free machining in these two cases means higher sulphur content. With sulphur incusions [manganese sulphide] you might not get a perfect mirror finish when polishing. Machineability of 410 is better than 304 as 304 is "gummy" as machinists call it. I would guess that most use 416 in the un heat treated form.

|

|

#3

|

||||

|

||||

|

Something to concider is that the 4xx series is austenitic which makes it able to be held with a magnet (a important trait on small pieces) but the 3xx series of stainless is non-magnetic.

Gary |

|

#4

|

||||

|

||||

|

Gary, you have that backwards. 300 is austenitic [nonmagnetic] , 400 is martensitic [magnetic]

|

|

#5

|

|||

|

|||

|

In other words, I can't go wrong with 416.

Thanx, Pat |

|

#6

|

||||

|

||||

|

Another consideration that may be worth noting....416 is real easy to work... a pleasure to shape, carve, etc. It's long been the favorite of engravers...I always use 416 for any part of my knives that I intend to embellish with any sort of carving.

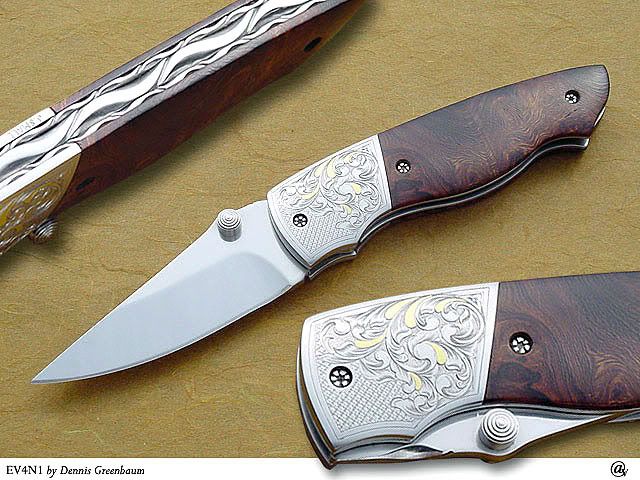

The knife in the photo is an "oldie but goodie"...from years ago, back when I was still making kit knives. It came to mind for this thread because it was my first time to use 416 for bolsters. As always, I had replaced the stock bolsters with my own. Knowing that my customer wanted the knife to be engraved, I had decided to go with 416 for the bolsters, and I purposely made them quite oversized in order to provide the engraver with plenty of "canvas"... Jim Small did a marvelous job on the engraving (of course) and I specifically recall him commenting afterwards what a pleasure it had been to work with the large, easy-to-engrave, 416 SS bolsters. That was my first time to use 416 for my bolsters....I've been using it ever since. BTW- I also made the backspine out of 416. I think the liners may have been 3xx series.  Dennis Greenbaum

Last edited by Osprey Guy; 09-19-2007 at 06:33 PM. |

|

#7

|

|||

|

|||

|

Nice job on that knife, Dennis.

Yes, 416 does seem to be the popular one. I called Pop's knife supply the other day and he said he has a hard time finding a supplier for the barstock anymore. He will bring some to the Cambridge, Ohio show in October if he has any. Also last week I picked up a 30" bar of 3/8X1" 416 from a local supplier and he was suprised he had any at all. The searching for 416 is what prompted my original question. I would like to settle on a choice with good availability and learn how to work with the steels properties to make my work a little more consistent. Thanks for the comments. Pat |

|

#8

|

|||

|

|||

|

Very sad to hear that 416 is getting harder to find over there. Here in the UK it is impossible to get rectangular bar, and there are only one or two places that sell round bar, but you have to buy in industrial quantities

I am not sure what 416 gets used for in industry. The 300 series get used in all kinds of plant equipment, particularly the food industry. The problem I have had with steel sourced that way is that it is often part hard for strength and hence is a bear to work with. __________________ Chris |

|

| Tags |

| hunting knife, knife, knives |

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|